Thermal barrier coatings and its manufacturing

Avoid delamination and spallation from substrate even during high temperature exposition for a long time

Overview

Thermal barrier coating has become essential to apply to combustor and gas turbine blade used for power generation, since a ceramic coating of about 300 mm can provide a thermal barrier effect of about 100 ℃. However, degradation over time appears when it is used for a long period of time in high temperature environment. In particular, if the coating delaminate, the base material, Ni-based superalloy, is exposed to an environment that exceeds its operating temperature, which could lead to a serious accident. In addition, higher combustion temperature is being considered for higher efficiency for the future, and there is a need to improve the strength of the thermal barrier coating/bond coat interface.

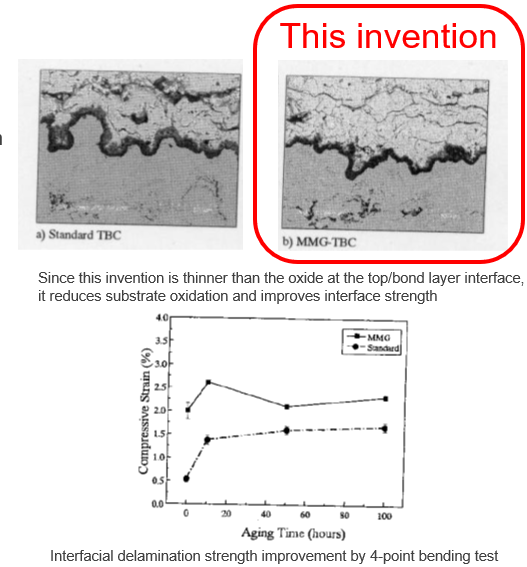

This invention is able to provide a thermal barrier coatings that does not delaminate from the base material even after prolonged exposure to high temperature environment, and its manufacturing method. This invention uses mechanochemical reaction to improve the bonding strength of dissimilar material interface such as thermal barrier coating/bond layer. It is able to activate the bond layer powder and limit the thermally grown oxide formation in the thermal barrier coating layer by mechanical loading. The interface strength between the substrate and the bond layer has been improved by about 4 times.

Interface strength improvement

Product Application

・High-temperature component in advanced gas turbine

・Aero jet engine

IP Data

IP No. : JP4644803

Inventor : OGAWA Kazuhiro, SHOJI Tetsuo, ICHIKAWA Yuji, SOLONENKO Oleg, POLBOYAROV Vladimir, TANNO Masatoshi

keyword : ThermalBarrierCoating, Coating, MechanochemicalProcess