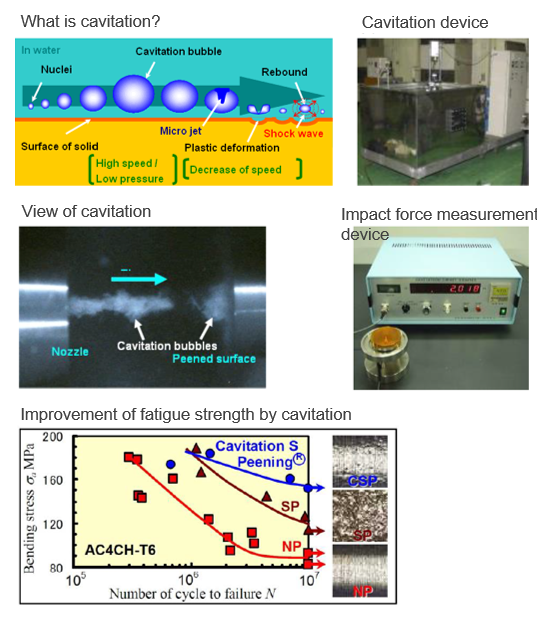

Surface modification method using flow cavitation

Surface modification method to improve fatigue strength of metallic material by impact force generated during bubble collapse

Overview

Cavitation is a phenomenon where a liquid becomes an air bubble due to the decrease of saturated steam pressure of the liquid caused by pressure decrease occurred by the velocity increase of a liquid. In particular, group-row cavitation consisting of microbubbles produces a large impact force. Cavitation shotless peening which uses this phenomenon, has a smoother machined surface and higher fatigue strength than the method which uses steel balls (shot peening).

Operation in air is also possible without using a water tank, by injecting a high speed water jet into a low speed water jet.

Product Application

・Processing device to improve fatigue strength

・Processing device to apply compressive residual stress

・Equipment to promote animal and plant growth

IP Data

IP No. : JP5066703, JP4635206

Inventor : SOYAMA Hitoshi

keyword : Measurement, Machine, Control