Non-contact & non-destructive inspection method for thermal barrier coating

Degradation evaluation of ceramic thermal barrier coating for gas turbine thermal power plant by using few GHz microwave

Overview

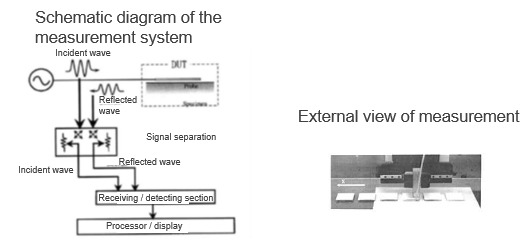

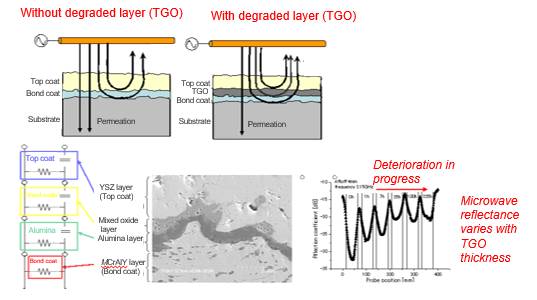

This invention is about a non-contact & non-destructive inspection method for evaluating the degradation with the age of thermal barrier coating on heat resistant metallic material by using microwave. The formation and growth of thermally grown oxide (TGO) which is formed as a result of aging, is evaluated for ceramic coated element used in gas turbine thermal power generation, and the interfacial strength is indirectly evaluated. YSZ (top coat) is used in ceramic coating for gas turbine element, and MCrAlY alloy layer (bond coat) is inserted between the YSZ and the substrate (Ni-based superalloy) to increase delamination resistance. This element is known to form TGO on the bond coat as the material deteriorates, so the element life evaluation is possible by evaluating TGO.

Features・Outstandings

Product Application

・Lifetime evaluation of high temperature element for gas turbine

・Interface evaluation of ceramic coated element

Related Works

[1] OGAWA Kazuhiro, MIURA Hideo, SHOJI Tetsuo. Material and Process Vol.19(2006) No.1

“Non-destructive evaluation of aged thermal shield coating by using the high frequency transmission property method”

IP Data

IP No. : JP5205608

Inventor : OGAWA Kazuhiro, MIURA Hideo, SHOJI Tetsuo, SUZUKI Mikiko

keyword : Non-destructiveInspection, High-frequencySignalTransmissionTechnique