Method of manufacturing torque sensor

Method of manufacturing torque sensor for forming spray coating.

Overview

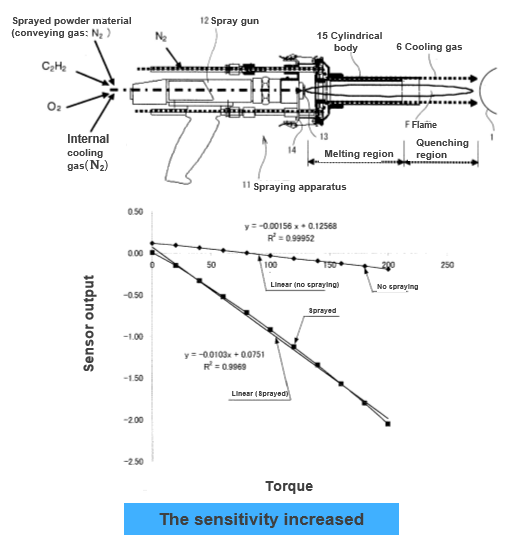

Since two characteristics of high permeability and high magnetostriction are required for the magnetic material constituting the magnetostrictive part of the rotating shaft of the conventional torque sensor, an amorphous alloy is suitable. However, when a amorphous alloy foil is fixed to the surface of the rotating shaft with an adhesive, there is a problem that sufficient detection characteristics cannot be obtained because adhesion to the rotating shaft is poor. In addition, even when a metallic spray coating is formed on the surface of the rotating shaft by a high-speed spraying process, there is a problem that a fine amorphous metal powder must be used, which increases the manufacturing cost.

The invention has made it possible to provide a torque sensor and its manufacturing method with improved torque detection characteristics and manufacturing cost. The invention has a magnetostrictive part including a metallic glass coating on the surface of a rotating shaft. The metallic glass coating is characterized in that a flame including the metallic powder is jetted to melt the metallic powder, and the metallic glass coating is formed using a cooling method before the flame reaches the surface of the rotating shaft. Thus, a magnetostrictive part is formed easily and quickly. It also exhibits excellent characteristics for torque detection.

Features・Outstandings

Product Application

・Torque sensor

IP Data

IP No. : JP5940531

Inventor : SAOTOME Yasunori, AMIYA Kenji

keyword : torque sensor、spray coating