Wavefront control element and diffraction grating

Manufacture small structure in short time by controlling the metallic glass material shape

Summary

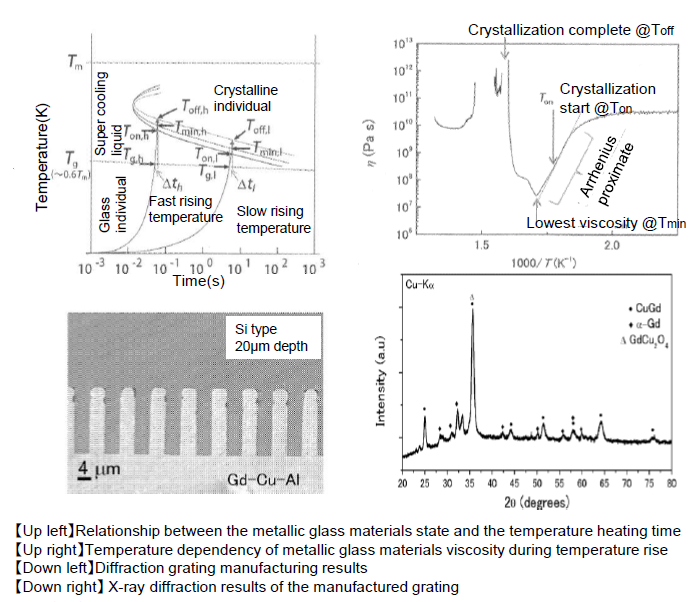

In X-ray and neutron interferometry, the wavefront control elements must

be precisely shaped. Grating with high-precision shape is required

especially for interferometer where metallic glass grating is used as

wavefront control elements. To obtain a metallic glass grating, it is

preferable to bring the grating as close as possible to the crystallization

initiation temperature with fast heat-up. However, more the temperature is

high, more the lifetime time for the supercooled liquid is short. Therefore,

the metallic glass material has to be molded while the viscosity is still high.

In addition, the conventional grating manufacturing has difficulty to obtain

small structures and the process needs long time.

This invention is able to form a metallic glass material with low viscosity,

and to provide a manufacturing method, wavefront-controlled elements

and diffraction grating with structure smaller than few 10μm having precise

shape control in a short time. This invention has a process of heating a

metallic glass material in a supercooled state to a temperature above the

crystallization begins, and mixing until the crystallization is completed.

Effect

Able to control shape precisely and to produce small structures of less than few 10μm in a short time

Application

・X-ray / neutronTalbot interferometry

IP Data

IP No. : German patent 602016026590.7, US patent publication 2018-0187294, WO2016/208517

Inventor : KATO Hidemi, YASHIRO Wataru

keyword : Measurement, Machine, Control