Oxide ceramics – carbon composite and its manufacturing process

Manufacturing Li4Ti5O12-carbon composite by using microwave at low cost!

Summary

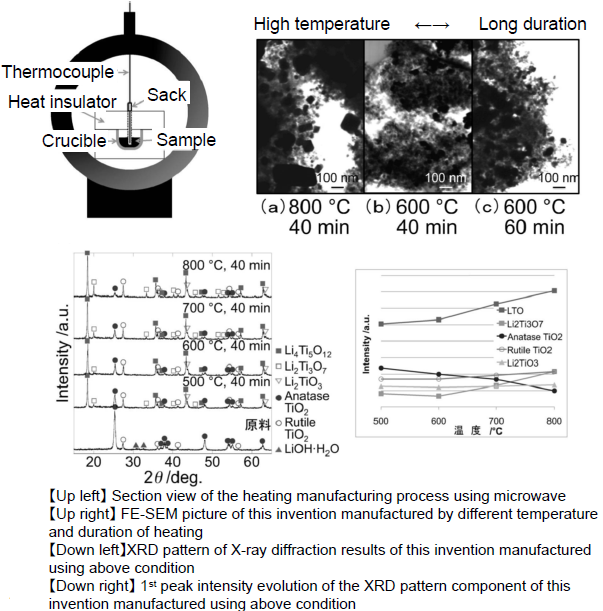

Ceramics – carbon composite having multi-function is developed in the

recent years. However, the composite is heated at high temperature for a long

time during the manufacturing process so the particles are sintering between

them and the Li4Ti5O12 nano particles able to generate high power cannot

be obtained. Moreover, the synthesis method is complex and uses expensive

raw materials so the manufacturing cost is high.

This invention can provide oxide ceramics – carbon composite and its

manufacturing process with reduced cost. This invention manufacturing

process is to mix raw material of oxide ceramics made by LiO2 and TiO2 with

carbon and fire with microwave in order to create Li4Ti5O12 carbon

composite. As result, Li4Ti5O12 crystalline particle which is an oxide

ceramics having particle diameter lower than 250nm; and oxide ceramics –

carbon composite having above mentionned carbon bond on the crystal plane

(111) and (200) of the oxide ceramics – carbon composite were obtained.

Effect

Manufacturing oxide ceramics carbon composite at low cost

Application

・Electric conductive, heat resistant, corrosion-resistant, heat conductive, anti-heat shock material

・New function material development

IP Data

IP No. : JP6598206

Inventor : HAYASHI Yamato, TAKIZAWA Hirotsugu

keyword : Material