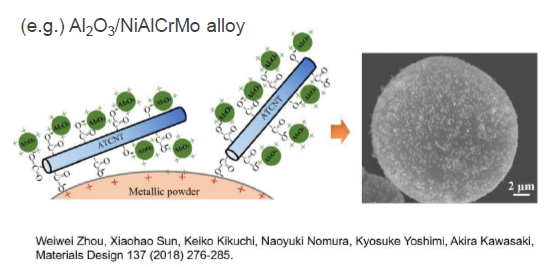

Metal / ceramic composite material

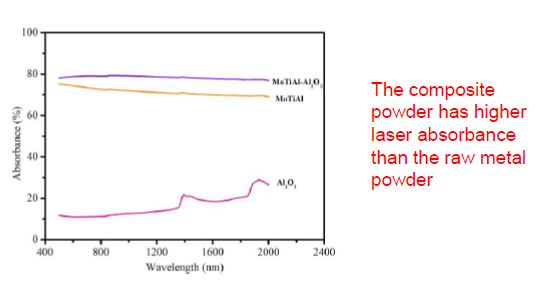

Possible to produce high laser absorption metal powder with finely dispersed ceramic on the surface, and metal/ceramic composite material having complex shape!

Overview

Metal and ceramic repel each other when mixing due to their

positive surface charge. So since they are dispersed away, the

composite can not be formed. The conventional technology uses a

binder composed mainly of polyvinyl alcohol to glue metal and

ceramic. This is then sintered in order to make a composite powder.

However, the binder reduces the functionality due to compositional

change (specifically, mechanical property deterioration, optical

absorbance decrease, etc.) and handling during production is difficult.

This invention is able to easily make ceramic / metal composite by

using carbon nanotube (CNT). Application of various powder to bulk

material is expected, such as sintered material and composite

material by 3D printer. It is also possible to create a pure composite

of metal / CNT, and this technology is expected to improve the antioxidation

property of the base metal material.

Features・Outstandings

Product Application

・Metal / ceramic composite material having complex shape

・Metal / CNT composite material

・Heat resistant material requiring ceramic protective coating

・Corrosion resistant material

・Hard material, etc.

IP Data

IP No. : JP6934674

Inventor : NOMURA Naoyuki, YOSHIMI Kyosuke, KAWASAKI Akira, ZHOU Weiwei

keyword : Material