High-density plasma sputtering device

Damage-less sputtering / Independent control of ion energy and flux / Useable in ferromagnetic target

Overview

With the increase of request for device miniaturization and thin

crystal film quality improvement, the ion damage on substrate has

become a major issue in sputtering. The magnetron sputtering

method is widely used but since the plasma is formed directly

between the target material and the substrate, “① it is difficult to

avoid ion damage”. This issue is amplified when generating highdensity

plasma. In addition, since a single power supply is

responsible for both the plasma generation and ion attraction, “② it

is impossible to independently control the ion flux and energy flowing

into the target material”. Moreover, since the plasma is confined by

the magnetic leakage flux on the target surface, “③ it is difficult to

use for ferromagnetic material target”.

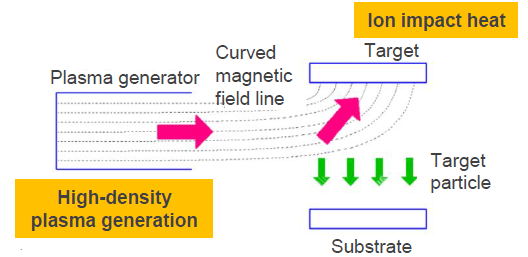

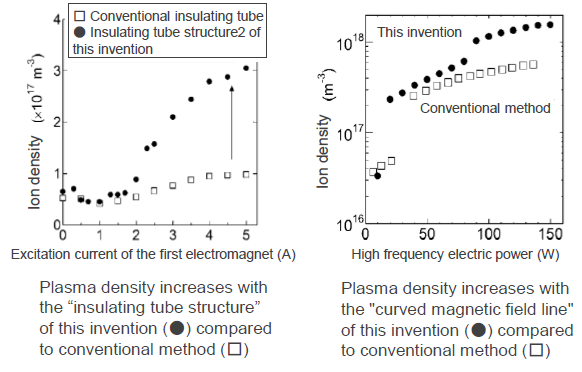

This invention solves above ①/②/③ issues by generating highdensity

plasma with helicon discharge and by controlling the plasma

shape with a curved magnetic field, etc. This invention could also be

considered to be used as a heating mechanism of the target material,

or as an uniform & fast film deposition.

Features・Outstandings

Product Application

・High quality crystalline thin film formation without damage to substrate

・Film deposition from a thick ferromagnetic target material

・Film deposition of target material by repeated evaporation & sublimation

・Uniform film formation on large diameter target and substrate

Related Works

[1] T. Saito, K. Takahashi, et al., Vacuum, 163, 269 (2019).

[2] K. Takahashi et al., Vacuum, 171, 109000 (2020).

[3] TAKAHASHI Kazunori,Plasma Technologies in an Innovative

Semiconductor Industrial System: Minimal Fab- Multi-Target Sputtering

Tool Using a Helicon Plasma Source, J.Plasma Fusion Res. 10, 522 (2020).

IP Data

IP No. : WO2018-143164, US10854448

Inventor : TAKAHASHI Kazunori, FUKUSHIMA Jun, ANDO Akira, SASAKI Yasumasa

keyword : Measurement, Machine, Control