Swelling followed by ball-milling for waste wire-harness recycling

Highly efficient and accurate separation of copper wires and PVC coating

Overview

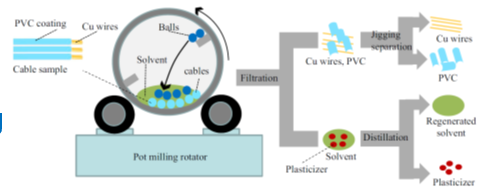

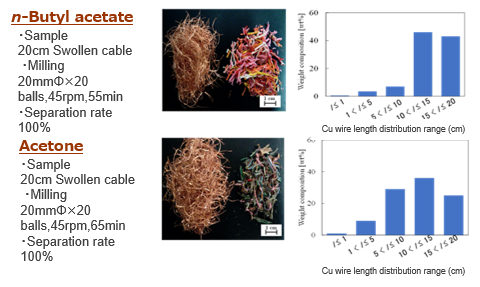

Wire harnesses (WHs), the main target of this technology, are mainly used in automobiles and consist of bundles of thin wires that connect each component and are responsible for transmitting electrical signals and supplying power. Increased demand is expected with the rapid growth of electric vehicles in the future, and the development of efficient recycling technology for used WHs is strongly desired. To secure domestic resources and realize a decarbonized society, it is vital to recycle not only metal wires but also plastic coating materials. Chopping or comminution treatment is a common separation technology for treating used WHs, while it has limitations for mechanically recycling recovered plastic coating because it contains fine copper particles that are impurities for recycling. This invention enables the separation, sorting,and simultaneous recovery of copper wires and polyvinyl chloride (PVC) coating without the formation of fine particles by applying moderate impact in the ball mill equipment after swelling the coating material with organic solvent.

Features・Outstandings

Product Application

・Wire Harness Recycling Separation and recovery of copper wire, aluminum wire, PVC, etc.

Related Works

[1] S. Kumagai*, T. Yoshioka et al., Scientific Reports, 10, 10754 (2020).

[2] S. Kumagai*, T. Yoshioka et al., Journal of Material Cycles and Waste Management, 23, 461 (2021).

IP Data

IP No. : JP2021-100349、 JP6832539(granted)

Inventor : Toshiaki Yoshioka, Shogo Kumagai, Tomohito Kameda

keyword : Environment, Energy