Electrochemical transfer of tramp element from molten iron

Continuous Cu separation from molten Fe by molten oxide electrolysis

Overview

Recycled smelting using steel scrap can significantly reduce carbon usage and CO2 emission compared to current method, and it is an effective mean to reduce the actual increasing amount of steel scrap.

However, the contamination of tramp elements, such as Cu/Ni/Sn, which are difficult to remove by oxidation and evaporation, causes the property and workability deterioration of steel material. In addition, since tramp elements are concentrated each time the steel scrap is recycled, they become the cause of the inability to increase recycling rate. The conventional method of copper removal using sulfide flux has been considered, but this is a batch process using a large amount of sulfide.

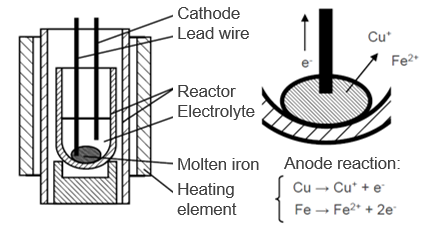

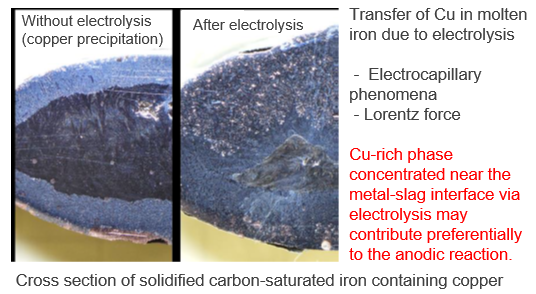

This invention is about a technology to promote ion separation of Cu in molten iron into molten slag using electrochemical method, which enables in principle continuous processing. Moreover, not only purification of molten iron but also recycling of recovered electrodeposited copper can be considered.

Separation of Cu in molten iron

Product Application

・Recycled smelting with steel scrap

・Continuous tramp elements removal

Related Works

[1] Uchida, Y., Matsui, A., Kishimoto, Y., & Miki, Y. (2014). Removal ofCopper from Molten Iron with Na2CO3-FeS Fluxes. Tetsu-to-Hagané, 100 (2014), 769-777.

[2] S.H. Lee & D.J. Min. (2020). Effects of electrochemical potential on sulfur removal in the molten CaO-SiO2-Al2O3 system. Sep. Purification Technol. , 236 (2020), 116231

IP Data

IP No. : JP2022-12951

Inventor : NATSUI Shungo, SATO Takahiro, ITO Akihisa, NOGAMI Hiroshi, UEDA Shigeru

keyword : recycled smelting, steel scrap, continuos tramp elements removal, Cu/Ni/Sn separation, reduce CO2, electrochemical method