3D coke deformation recognition system by deep learning

Able to learn and estimate the coke strength after reaction (CSR) and deformation pattern

Overview

The gas permeability in the blast furnace deteriorates due to excessive coke

degradation during the low coke rate operation in order to reduce CO2 emission.

The coke strength after reaction (CSR) is a parameter to evaluate coke quality

and is used as an indicator of permeability in blast furnace operation.

However, CSR is an index that averages the high-temperature deformation

behavior of each cokes, and can’t estimate the complex deformation behavior of

individual coke particles. Existing method for flow phenomena visualization and

clogging prediction using kinetic model is computationally demanding and limited

in the ability to analyze stochastic deformation behavior in a scaling manner.

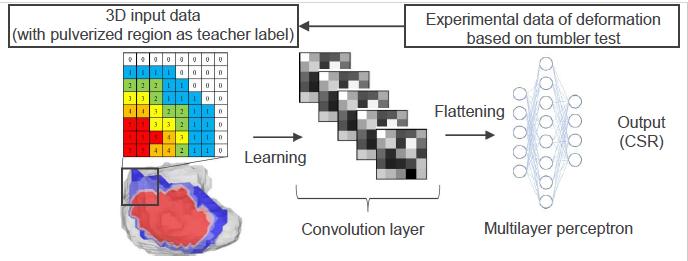

This invention applied deep learning using Deep Neural Network (DNN), which

is a typical AI method, to the coke 3D deformation process. Machine learning

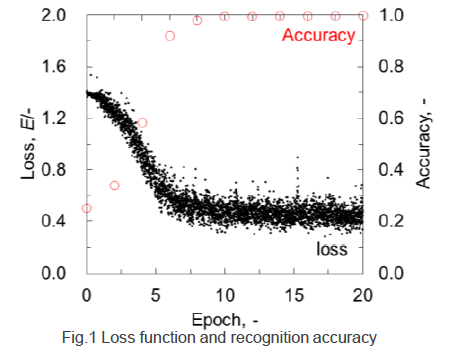

was performed to estimate of the deformation process using DNN. As shown in

fig.1, the loss function (deviation from the “estimated value”) decreased with the

number of learning sessions, and the recognition accuracy shows over 97%. This

indicates that DNN can classify the deformation of every CSR accurately and

reduce the computational load for coke deformation prediction remarkably.

Therefore, machine learning can easily recognize the coke 3D shape

deformation which is difficult to recognize intuitively.

Over 97% CSR recognition accuracy by learning from experimental data

Product Application

・Periodical measurement of coke deformation pattern based on CSR value

in a production site

・A simple blockage estimation system of filling layer for coke mixing

process

・Creation of boundary condition data for kinetic model

Related Works

[1] Natsui, S., Hirai, A., Terui, K., Kashihara, Y., Murao, A., Miki, Y., & Nogami, H.

(2021). Method for Simulating Gas Permeability of a Coke Bed Including Fines Based

on 3D Imaging on the Coke Particle Morphology. ISIJ International, Vol. 61 (2021),

1814-1825

[2] Tammina, S. Transfer learning using VGG-16 with deep convolutional neural

network for classifying images; Int J. Sci. Res. Public., 9(10), (2019), 143-150.

IP Data

IP No. : JP2021-098241

Inventor : NATSUI Shungo, NOGAMI Hiroshi, HIRAI Azuma

keyword : Measurement, Machine, Control, Environment, Energy