Rotary reactor

Promotes gas-liquid reaction in CO2 absorption and salt manufacturing process, resulting in equipment downsizing and energy saving

Overview

For CO2 fixation and usage, there are many systems that involve mass transfer, reaction and absorption between gas / liquid; for example the reaction of an amine absorption solution or calcium solution with a dilute CO2containing gas. The conventional spray, bubble, packed and wetted wall columns are increasing in size in order to increase the reaction interfacial area and detention time.

For the concentration, crystallization and drying in the salt manufacturing process in Japan, the conventional shaft kiln method has the same issue of the equipment size increase. The high energy consumption is also an issue since the bubbles are generated by boiling the liquid phase.

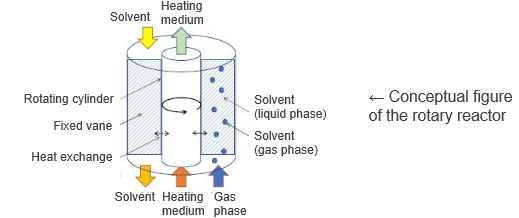

This invention achieves the equipment downsizing by increasing the gas-liquid reaction field area by using the phenomenon that the gas phase introduced into the heat exchange mechanism using a rotary double tube is refined and retained in the solvent by the agitation and shearing force of the rotating cylinder. The heat transfer rate is improved and the energy saving is possible thanks to the removal of precipitate and boundary film on the rotating cylinder.

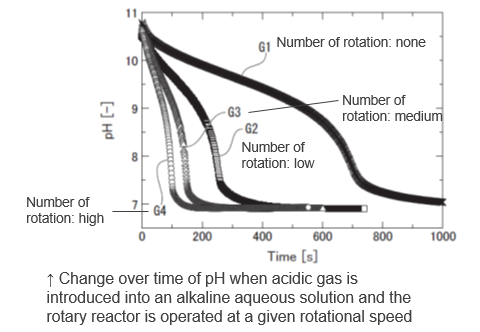

Response speed increases with the rotation speed

Product Application

・Gas-liquid reaction process in CO2 absorption

・Concentration, crystallization, drying processes in salt manufacturing process

・Other fluid-to-fluid reactions (gas-liquid, liquid-liquid)

IP Data

IP No. : WO2023/176827

Inventor : MARUOKA Nobuhiro

keyword : salt making, heat exchange, gas-liquid reaction, CO2 absorption