Multilayer ceramics and methods of production

Improves the coating of metals and metal compounds, prevents peeling and cracking, and ensures corrosion resistance!

Overview

Silicon carbide materials and silicon carbide fiber-reinforced composites are expected to replace Zircaloy and other metals as structural materials for next-generation nuclear reactors. However, these materials require anticorrosion coatings when they are exposed to radiation, high temperatures, and high-pressure water. Although metal coatings have been used in the past, there has been a problem that they cannot fully exert their anticorrosion function due to delamination and cracking of the substrate caused by thermal expansion coefficient differences and swelling differences.

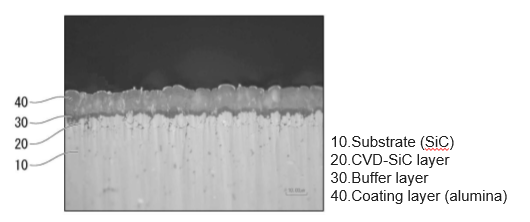

A silicon carbide layer, an intermediate layer and a coating layer are laminated on a substrate. As a result, it has become possible to provide a silicon carbide material or a silicon carbide fiber-reinforced composites composed of full ceramics with improved anticorrosion function by alleviating thermal expansion coefficient difference and swelling difference with a base material.

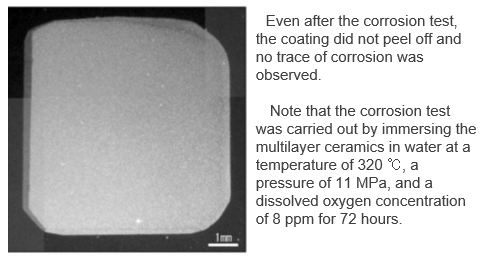

Corrosion test

Product Application

・Next generation light-water reactor and Small Modular Reactor、Reduced-Moderation Water Reactor、Micro Modular Reactor

・Nuclear fusion reactor and geothermal plant

Related Works

[1] Sosuke KONDO, Corrosion of SiC and Development of Corrosion Protection Technology for Ceramics, J. Plasma Fusion Res. Vol.98, No.8 (2022) 338-343

[2] Sosuke KONDO, Hirokazu KATSUI and Kazuya SHIMODA, Development of Corrosion-Resistant Coating Technology for Ceramic-Based Nuclear Reactors, J. Surf. Finish. Soc. Jpn., Vol.74, No.12, 2023 Pages 666-672

IP Data

IP No. : JP2023-127495

Inventor : Sosuke KONDO et al.

keyword : CorrosionProtection, SiC, NuclearFusionReactor