Provide carbon fiber reinforced plastics with good metal coating adhesion

Manufacturing method of metal-coated fiber reinforced plastics

Overview

Carbon fiber reinforced plastics (CFRP) are used in many fields because of its light weight, high strength and corrosion resistance. However, CFRP is known to have low electrical conductivity. So when it is used in aircraft fuselage as example, there is a risk of damage due to lightning strike. Therefore, increase conductivity by forming a metallic film on the CFRP surface (metallization) is expected as a method to solve this issue.

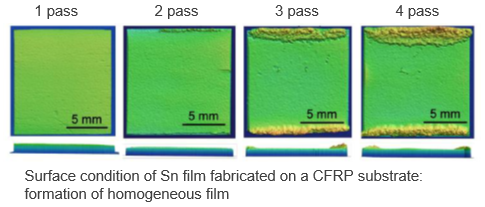

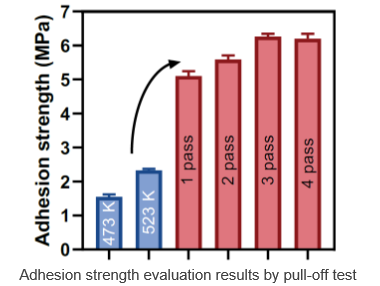

The cold spray method, which can be applied at low temperature with only little damage to CFRP, is attracting attention as a metallization method. Preliminary study has examined a method of forming metallic coating consisting of tin [1][2]. However, tin/CFRP interface has low adhesion strength. The methods to improve adhesion strength have been developed, such as the use of additive or surface treatment of CFRP, but they are not industrially ideal due to cost.

This invention is about metal-coated CFRP with improved adhesion strength by using a simple method that does not require pre-treatment or post-treatment, and its manufacturing method.

Adhesion strength is more than twice than the conventional method

Product Application

・Aircraft

・Automobile

Related Works

[1] Sun J, Zhou S, Yamanaka K, Ichikawa Y, Saito H, Ogawa K, et al. Thermal Effects in Sn Coating on a Carbon Fiber Reinforced Plastic by Cold Spraying. Journal of Thermal Spray Technology 2021;30:1254–1261.

[2] Sun J, Yamanaka K, Zhou S, Saito H, Ichikawa Y, Ogawa K, et al. Adhesion mechanism of Sn coatings on the carbon fiber reinforced plastics using cold spray technique. Applied Surface Science 2022;579:151873.

IP Data

IP No. : JP2022-183535

Inventor : YAMANAKA Kenta, CHIBA Akihiko, SUN JIAYU, OGAWA Kazuhiro

keyword : Material, Measurement, Machine, Control