Non destructive inspection by magnetic hammer testing with TMR sensor

High accurate detection of defect and thinning in structure containing magnetic material. No magnetization required, room temperature operation, low cost, compact size.

Overview

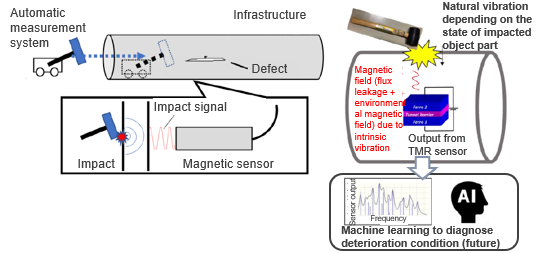

For non destructive inspection of defect such as inner surface of piping, etc., conventional percussion method has the disadvantage of being week to noise and having low spatial resolution (difficult to determine exact location). The magnetic leakage flux testing method being also a conventional method, overcomes the previous disadvantage, but it is not suitable for underground piping due to its difficulty to detect small defect, cost & time required to magnetize inspection object, and the large unit size that incorporates a permanent magnet.

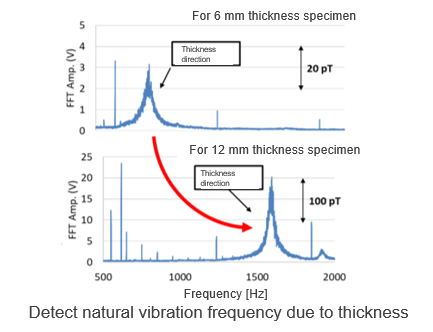

The percussion testing method proposed in this invention uses a TMR sensor to measure and analyze the natural frequency of a structure made of magnetic material from micro vibration to diagnose deterioration. The advantage of this method is "high spatial resolution and noise immunity because the magnetic field is measured at a short distance (2-3 cm) instead of acquiring sound wave at a long distance“, "suitable for underground piping because it targets demagnetized magnetic material" and "low sensor and calculation cost". In addition, facility that is constantly undergoing micro vibration may be able to perform the magnetic hammer testing without applying an external force.

Current detection resolution is 0.3 mm

Product Application

・Non destructive inspection of defect and thinning in structure containing magnetic material, such as steel pipe/body, train rail, reinforced concrete building, bridge, etc.

・Especially underground buried piping, etc.

Related Works

[1] J. Ito, M. Al-Mahdawi, M. Oogane, “Magnetic Hammer Testing with Tunnel Magnetoresistive Sensors”, presented at Intermag conference, 2023.

IP Data

IP No. : JP2023-075174

Inventor : OGANE Mikihiko, ITO Jun

keyword : Non-destructiveinspection, defectcheck, curvaturecheck, magnetichammertesting, TMRsensor, noiseimmunity, compact, lowcost, magneticleakagefluxtestingmethod, percussionmethod, steelbody, bridge, trainrail, undergroundpipe