Light curing high strength resin mold

Indentation modulus 8.4 GPa! Resin replica mold more solid than polyimide

Overview

High production cost of mold (plate) is a major challenge to promote the use of nanoimprint technology. Replica mold of an expensive original mold is essential for cost reduction. Especially, replica mold that can resist to repeated usage has been expected. The resin replica mold currently in practical use is limited to a few mold transfer and has low repeat durability.

This invention is about a resin replica mold that is solid and repeatedly durable. This mold consists of an organic/inorganic hybrid material with inorganic particles dispersed in resin and has a higher indentation modulus than polyimide. Since fluidity is maintained even the inorganic particles mixing ratio is 60 wt%, the product can be easily manufactured by pressing the original plate mold and curing by light irradiation. Moreover, it is to both thermal and optical nanoimprinting because it has both heat resistance and ultraviolet light transmittance.

Effect / Product Application

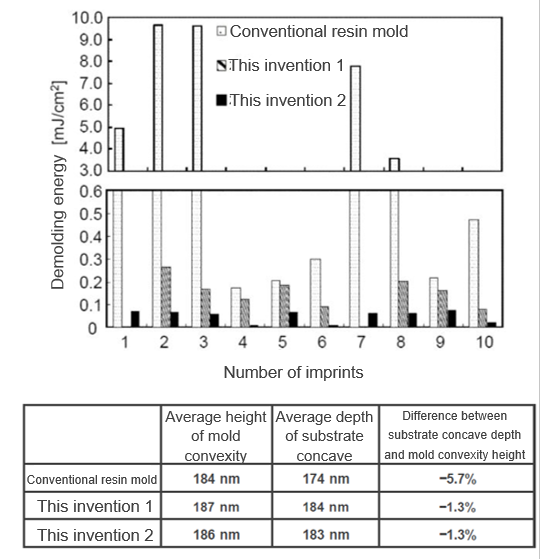

The high demolding force of conventional resin mold causes the defect of the mold pattern. Since this invention has much smaller demolding force than conventional resin mold, there is very little pattern defect even after repeated imprinting. When silica particles are used as inorganic particles, due to high compatibility with release agent containing silane coupling agent, it can further reduce demolding energy. For manufacturing replica of original mold with coarse and dense pattern, it is effective to apply resin to the substrate using stencil printing.

IP Data

IP No. : JP5879086

Inventor :NAKAGAWA Masaru, KUDO Shimpei, NAGASE Koichi,YUN Min Cheol, KUBO Shoichi

keyword :Electronics, Hardware