Mo-Si-B-Ti-C alloy

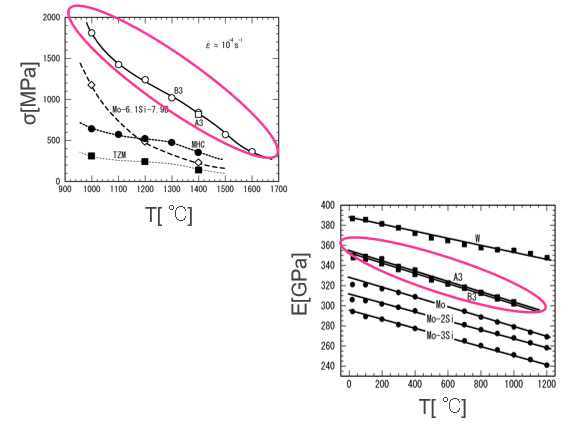

Formation of high-strength / high-rigidity / high heat-resistant Mo alloy that can be cast (able to melt under 2000℃)! Equivalent to Ni-based alloy!

Summary

Currently, molybdenum alloys are formed by extrusion of powder sintered bodies due to their high melting point. Therefore, cutting is required in order to form complex shapes, which increases the manufacturing cost. In addition, if a body is formed by the powder sintering, the strength is decreased.

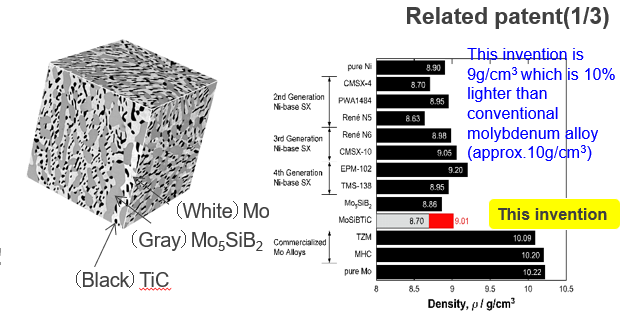

In this invention, light / high strength / high heat resistance molybdenum alloys can be easily fabricated by the melting and casting method, which can be applied for complex shapes. New molybdenum alloys with melting point below 2000℃.

Effect

Product Application

・Machining tools for friction stir welding, etc.

・Special molds

・High-pressure turbine blades for jet engines, etc.

・High-temperature, high-pressure vessels.

IP Data

IP No. : JP 5876943

Inventor : YOSHIMI Kyosuke, MARUYAMA Kouichi, GOTO Takashi,etc.

keyword : Material

High-temperature strength Mo-Si-B alloy

High temperature strength improvement by adding TiC and ZrC in Mo-Si-B alloy

Summary

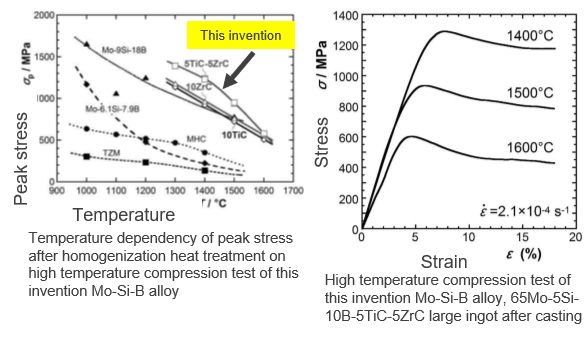

Non-cooling high temperature material is needed to run heat engine such as jet engine or gas turbine with high efficiency. Mo-Si-B alloy having high melting point and high temperature strength was focus from before but its property improvement is required. Moreover, Mo-Si-B alloy has high density and poor fracture toughness level at room temperature.

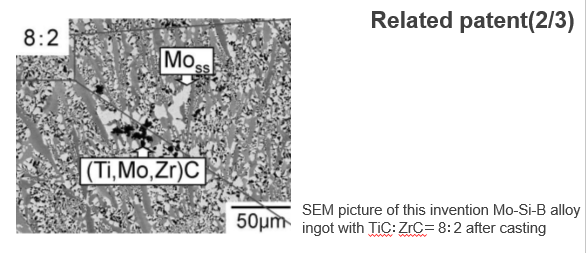

This invention can provide improved high temperature strength Mo-Si-B alloy including its manufacturing process, and also the tool of friction stir welding applicable for Ni-base superalloy and Ti alloy. By adding TiC and ZrC to Mo-Si-B allow simultaneously, the strength of Mo-Si-B is increased significantly. Moreover, this invention’s Mo-Si-B keeps high temperature strength level with lower density and higher fracture toughness level at room temperature compared to the conventional Mo-Si-B alloy.

Effect

Product Application

・Tool for friction stir welding (FSW)

・Hot extrusion die

・Gas turbine, high pressure turbine wings for power generation

・Jet engine

IP Data

IP No. : JP 6841441

Inventor : YOSHIMI Kyosuke, NAKAYAMA Shunichi, et al.

keyword : Material

Oxidation resistant Mo-Si-B-Ti-C alloy

High resistance to oxidation up to at least 800℃

Summary

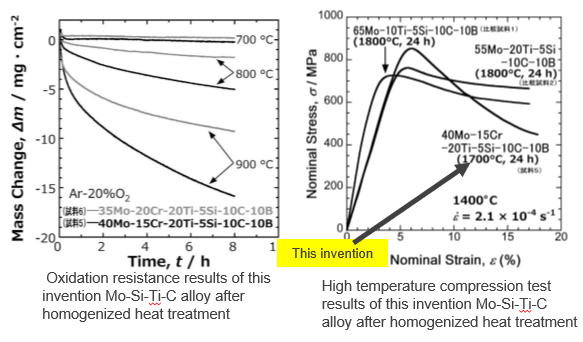

Research on non-cooling high temperature material is conducted in order to run heat engine such as jet engine or gas turbine with high efficiency. Mo-Si-B alloy is focus for its high melting point and high temperature strength. However, in order to applicate to high pressure turbine wings, the sliding friction will be generated at the interface between the turbine wings and the turbine disc. Therefore, the oxidation resistance at sliding friction temperature (approx. 700~ 800℃) needs to be improved.

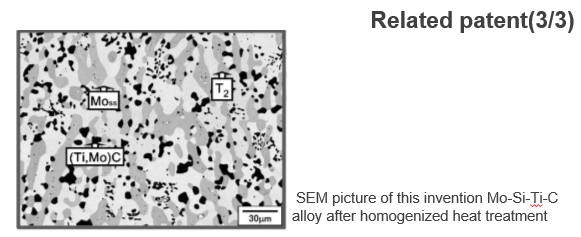

This invention can provide Mo-Si-B-Ti-C alloy with high oxidation resistance property at least until approx. 800℃, and its manufacturing process. The Mo-Si-B-Ti-C alloy of this invention includes Mo, Si, Ti, C and Cr and/or Al. Compared to Mo-Si-B-Ti-C alloy without Cr / Al, this invention is more light and hard. It can be manufactured by casting so there is possibility to upsize Mo-Si-B-Ti-C alloy.

Effect

Product Application

・Tool for friction stir welding (FSW)

・Hot extrusion die

・Gas turbine, high pressure turbine wings for power generation

・Jet engine

IP Data

IP No. : JP 2020-2451

Inventor : YOSHIMI Kyosuke, et al.

keyword : Material