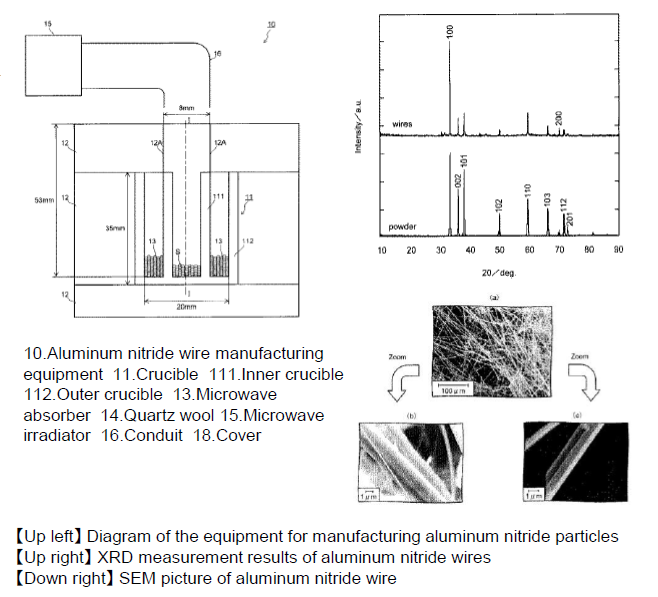

Method and apparatus for producing aluminum nitride wire

Suitable for thermally conductive filler and high-strength filler of sealing resin

Summary

Aluminum nitride (AlN) is known to be used as a filler in the sealing resin of

electronic components and semiconductors to efficiently dissipate the heat

due to its high insulation and thermal conductivity. AlN particles are

manufactured at high temperatures, but the conventional method can not

include a large amount of AlN particles in the resin. In recent years, the

improvement of sealing resin strength is required since the demands for

miniaturization of electronic components and semiconductors are increasing.

This invention can simply provide a new form of AlN that can be suitably

used as a thermally conductive filler and a high strength filler. This invention

is characterized by the process of mixing the carbon and alumina particles in

a crucible then to achieve a mixture ratio more important than the

stoichiometric mixture ratio required to produce AlN, and irradiating the

alumina particles with microwaves under a nitrogen atmosphere to reduce

and nitride the alumina particles with carbon particles. This invention

describes also the process of sublimating the AlN and attaching it to a

sample in a non-heated state to produce an AlN wire.

Effect

New AINs suitable for thermally conductive fillers and high strength fillers usage

Application

●Electronic components and semiconductor devices

IP Data

IP No. : JP 5569844

Inventor : TAKIZAWA Hirotsugu, HAYASHI Yamato, etc.

keyword : Material