Rare-earth free ferromagnetic particle powder showing BHmaxabove 6 MGOe

Realization of α"-Fe16N2particle powder with giant saturation magnetization

Overview

The international market price of neodymium has increased significantly in

recent years. The reason seems to be the increasing demand for windpower

generation and electric vehicle motor in China where the country is

promoting decarbonization as a national policy. In addition, the perspective

of economic security is discussed in Japan and there is a strong demand for

magnetic material which does not contain rare earth. Low cost Fe-N

magnetic material consisting only of iron and nitrogen has especially high

expectation. In particular, α"-Fe16N2 which has BCT structure and predicted

to have high magnetic saturation, has attracted much attention.

However, α"-Fe16N2 is a metastable compound that crystallizes when Fe-N

compound is annealed, and there is almost no report of its isolation as a

bulk material. The only few reported cases mention about eutectic crystal of

α"-Fe16N2 and stable phase, or the existence for only 10 days at 100°C, so

there is no example of α"-Fe16N2 single phase stable isolation as a bulk.

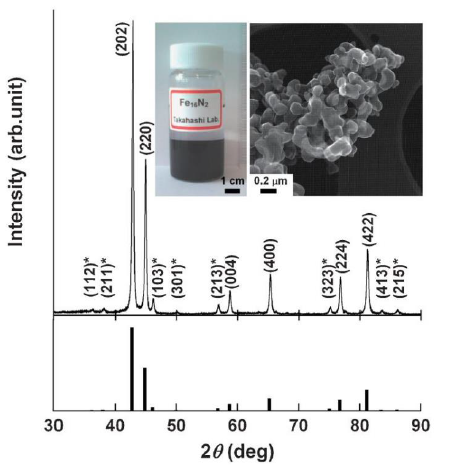

This invention is about the α"-Fe16N2 stable isolated powder. This magnetic

powder shows a BHmax of more than 6 MGOe (48 kJ/m3), which is higher

than ferrite and alnico. It also shows the saturation magnetization of 221

emu/g which exceeds metallic Fe, and the coercivity of more than 2 kOe

(160 kA/m) which is higher than alnico and comparable to ferrite. Since this

magnetic powder can produce magnet that outperforms ferrite and alnico

without using rare earth, it is expected to be used in motor, etc. as an

alternative to neodymium magnet which continues to rise in price.

Succeeded to isolate stably α“-Fe16N2

Product Application

・Anisotropic magnet

・Bonded magnet

・Compacted magnet

・Other applications such as substitute magnets for neodymium magnet in motor, etc.

Related Works

[1]Appl. Phys. Exp. 2013, 6, 073007. [2]Chem. Commun. 2013, 49, 7708.

[3]Chem. Commun. 2014, 50, 7040. [4]J. Appl. Phys. 2014, 115, 103905.

[5]Phys. Rev. B 2014, 90, 134427. [6]J. Magn. Soc. Jpn. 2017, 41, 58.

IP Data

IP No. : JP5769223, JP5822188, JP5831866 (And corresponding overseas rights)

Inventor : TAKAHASHI Migaku, SAKUMA Akimasa, OGAWA Tomoyuki, OGATA Yasunobu,

KOBAYASHI Naoya, Ruw an Polw atta Gallage, KOHARA Kaori

keyword : Material