New CoCr alloys with low Young's modulus, high wear and corrosion resistance, and superelasticity

Alloys with high fatigue life and free of nickel element

Overview

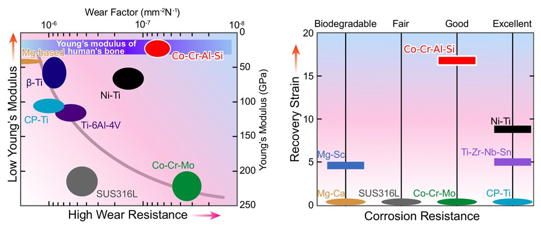

β-Ti and conventional CoCr alloys are widely used for artificial joints because of their superior mechanical properties. Some β-Ti alloys show superelasticity and low Young's modulus; however, they have low wear resistance. Conventional CoCr alloys show excellent wear resistance, but they have very high Young's modulus, which is about 10 times that of human bones. Since low Young's modulus and wear resistance are properties with a trade-off relation, there has not been a biomaterial that realizes both.

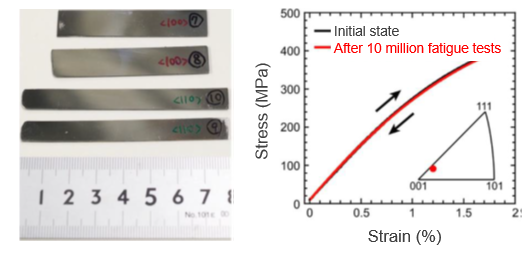

This invention is about new CoCr alloys that have an even lower Young's modulus than β-Ti alloys, which also boast high wear and corrosion resistance, and superelasticity. This invention shows a fatigue life of more than 10 million cycles up to a strain of 1.65% and it is expected to be the next-generation biological material.

These alloys are characterized by a large elastic anisotropy. In the <100> direction, they show a Young's modulus of 30 GPa, comparable to human bones, making it suitable to use for artificial joints and bone plates. In the <111> direction, they have extremely high Young's modulus of 300 GPa, making it suitable to use for stents.

Features・Outstandings

Product Application

・Artificial joint

・Bone plate

・Stent

Related Works

[1] Adv. Mater. 2022, DOI: 10.1002/adma.202202305.

IP Data

IP No. : International Publication WO2023/276283

Inventor : KAINUMA Ryosuke, OMORI Toshihiro, XU Xiao, ODAIRA Takumi

keyword : CoCr alloy, Super elastic, Wear resistant