Inducer with slit

Simple configuration suppresses cavitation instability

Overview

In a high-speed rotary pump such as used in a turbo pump for a rocket engine, cavitation occurs at the pump inlet. Therefore, a spiral auxiliary impeller with excellent suction performance called an inducer is installed in front of the pump main impeller to boost and transport stable liquid. Various techniques have been proposed to suppress unstable and asymmetric phenomena associated with cavitation in the inducer. However, conventional techniques have problems such as difficulty in machining, increased axial vibration and weight.

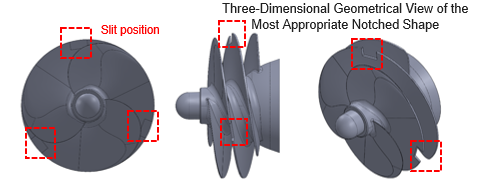

The present invention has attempted to solve the above problems by providing a slit (notch) in the inducer and optimizing the conditions of the position, depth and width of the slit. Specifically, it has the following features.

・ Provide axisymmetric slits on each blade of the inducer

・ A slit is provided upstream from the throat entrance on the outer peripheral side of the blade.

・ The inside length of the slit in the radial direction is shorter than the opening width, and the shape is wider.

With this configuration, it is possible to suppress the instability phenomenon while maintaining the step-up performance of the inducer.

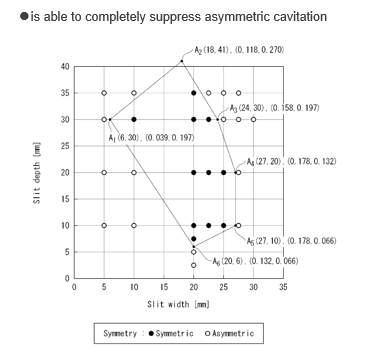

A slit condition was found to suppress the occurrence of cavitation

Product Application

・Turbo pump for rocket engine

・High-speed rotary turbopumps such as pumps for liquefied natural gas and liquid hydrogen

IP Data

IP No. : JP2023-67131

Inventor : IGA Yuka, KAWASAKI Satoshi

keyword : Inducer、Cavitation suppression