Method for producing tertiary alcohol

Improved productivity, environmental friendliness and cost reduction

Overview

Tertiary alcohols, such as tert-butyl alcohol (TBA), are useful as starting materials for pharmaceuticals, agrochemicals, and resins because they have higher oxidation resistance and hydroxyl group reactivity than primary/secandary alcohols. As an industrial process, there is a method of radical oxidation of isobutane under high pressure or without catalyst, but this process has problems of high energy load and low selectivity. As a solution, selective oxidation at ambient pressure using gold nanoparticle catalyst in the presence of hydrogen has been reported. However, there is concern about the risk of explosion because hydrogen and oxygen coexist in this method.

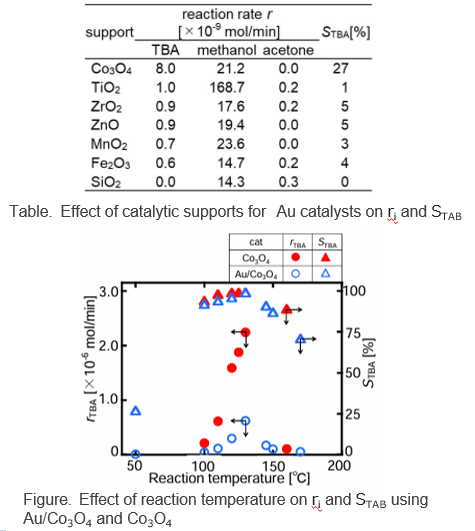

As a result of repeated studies to solve the above problem, the inventor found that isoparaffins can be selectively oxidized using molecular oxygen as an oxidant to produce the corresponding tertiary alcohols with high selectivity and high production rate by using a solid catalyst containing a transition metal oxide of periodic table group 6~9, which does not support gold, and using water instead of conventional hydrogen. In particular, when Co3O4 was used as a catalyst, the selectivity (STAB) of TBA in the product was as high as 99%.

TBA formation rate(rTBA) and selectivity(STAB)

Product Application

・Tertiary alcohol production

・Pharmaceuticals, agrochemicals, resin materials and petroleum additives

Related Works

[1] The 11th JACI/GSC Symposium

[2] Post symposium of TOCAT9 in Sendai

IP Data

IP No. : JP2022-117283

Inventor : TAKAHASHI Atsushi, ONO Masataka

keyword : tertiary alcohol、tertiary butyl alcohol、TBA