Batch fabrication method by laminating method

Batch fabricating of complex parts using 3D printing robots

Overview

In the fabricating industry, with the diversification of customer needs, the

demand for high-mix, low-volume production and complex fabricating

technology is increasing. In particular, for endoscopes, which are produced

in high-mix, low-volume production, the parts processing and assembly

work are generally carried out manually by skilled workers. However, there

have been problems such as variations due to individual differences and

time required for production by hand.

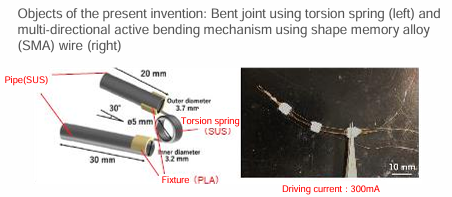

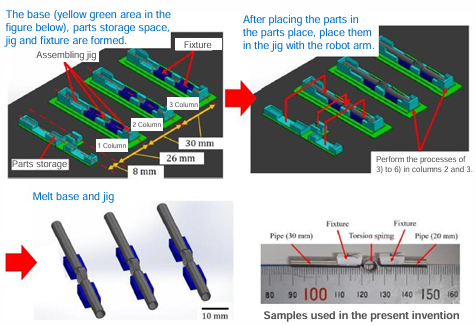

In order to solve the above problems, the present invention has developed

a method for automatically and collectively creating complex parts

fabricating and assembly processes using a 3D printer and a robot arm.

Specifically, a fixing table and a jig are laminated with a soluble material,

and the parts are arranged on the main body using a robot arm. Then, the

fixing table and the jig are dissolved (see right figure). We were able to test

and confirm the operation of this technology by applying it to the joint of a

chopstick endoscope used in otology (upper left figure) and a multi

directional active bending mechanism using shape memory alloy (SMA)

wire (upper right figure).

In the future, we aim to apply this technology to various minimally invasive

medical devices and some consumer products by mounting various micro

electronic components.

Outline of the batch fabrication process

Product Application

・Automation of high-mix, low-volume production

・Automation of complex parts processing and assembly operations

Related Works

[1] Proceeding of The 63rd Japanese Society for Biomedical Engineering(2024)

IP Data

IP No. : JP2024-077455

Inventor : HAGA Yoichi, TSURUOKA Noriko, HER Jun, ABE Shimpei

keyword : Robot Arm, 3D Printer